Changzhou Chengfeng Flowmeter Co.,Ltd for 30 years, has been in the study and progress, learning advanced foreign instrumentation equipment and technology, the introduction of advanced technology, and then based on the research and development of new technology, combined with the requirements of customers innovative products that meet customer needs, meet the requirements of customers, the pursuit of perfect quality, technical breakthroughs.

Summary:

LZB-()W/WB series micro flow rotameter diameter includes DN3,DN4,DN6,DN10 four kinds.which are featured with light structure,sensitive adjustment ,easy installation.They can measure micro gas and liquid,widely used for micro measure and analyses,environment protection, pharmacy,light industry,food,scientific research industries etc.This kind flowmeter also can be used together with analytical apparatus, environment protection instruments,medical facilities and other scientific experiment devices.

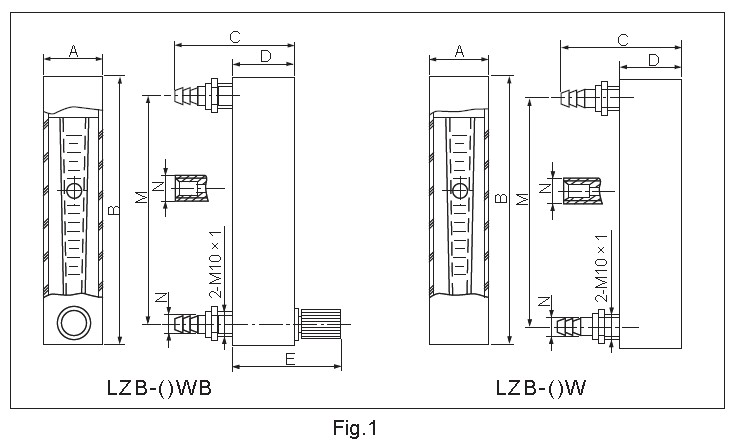

Outline and Installation Size:

LZB-()WB series flowmeter equip with control valves,LZB-()W series flowmeter without control valve,see the outline and installation drawing as following:Fig.1 and Table 1

|

Table 1 unit:mm |

|||||||||||

|

DN |

Model |

Size |

N |

Holes in equipment |

Remarks |

||||||

|

A |

B |

C |

D |

E﹡ |

M |

Hose |

Metal tube |

||||

|

3 |

LZB-3W |

26 |

136 |

50 |

24 |

<50 |

116 |

Φ8 |

M10×1 |

2-Φ11 |

Without customized design and connection size |

|

4 |

LZB-4W |

28 |

136 |

56 |

27.5 |

<52 |

116 |

Φ8 |

M10×1 |

2-Φ11 |

|

|

6 |

LZB-6W |

28 |

136 |

58 |

29.5 |

<55 |

116 |

Φ10 |

M10×1 |

2-Φ11 |

|

|

10 |

LZB-10W |

28 |

160 |

60 |

29.5 |

<55 |

140 |

Φ11 |

M10×1 |

2-Φ11 |

|

Notes:﹡Special for LZB-()WB series only.quick connection and swagelok connection is optional.

Technical Parameter:

Table 2

|

DN(mm) |

Model |

Measuring range |

Accuracy |

Length of taper tube(mm) |

Allowed measuring fluid state |

||

|

Water,20℃ |

Air,20℃,101325Pa |

Temperature(℃) |

Pressure(MPa) |

||||

|

3 |

LZB-3W |

0.4~4ml/min |

6~60ml/min |

4 |

100 |

0~60 |

≤0.2 |

|

4 |

LZB-4W |

16~160ml/min |

0.3~3L/min |

||||

|

6 |

LZB-6W |

40~400ml/min |

0.7~7L/min |

2.5 |

|||

|

10 |

LZB-10W |

0.1~1L/min |

3~30L/min |

120 |

|||

Material of Process Fluid Touching Parts:

Table 3

|

Parts |

Parts Materials |

||||

|

Base |

Connector |

Floater |

Taper tube |

Seal ring and shim |

|

|

Normal Type |

HPb59-1 brass |

HPb59-1 brass |

Agate,SS304,acrylic glass |

borosilicate glass |

NBR |

|

Anti-corrosion Type |

SS304 |

SS304 |

SS304,Agate |

borosilicate glass |

Fluorine rubber |

Notes:Other materials can be customized.

Installation requirements:

1.Before installation flowmeter should be transport protection with the plunger, fillers, etc.

2. Meter should be installed vertically on the no vibration of the pipeline, there is no obvious tilt.

3. Meter inlet joint should be connected with its cone piont.

4. Install the flow time, 4 to fixed connection pipe flowmeter, really should not make the glass tube produces stress.

5. Test medium to clean, if necessary, in the upstream flow meters installed filters.